When it comes to manufacturing, one of the big decisions you’ll make is choosing the right equipment. Among the many components that play a role in ensuring smooth operations, heat exchangers are the most important. They are used in almost every industry, such as food processing, milk production, etc. However, choosing the right heat exchanger for your manufacturing needs is not that easy. There are certain factors that you must consider while buying a heat exchanger. In this post, we will learn about major factors to consider when purchasing a heat exchanger.

What Is a Heat Exchanger?

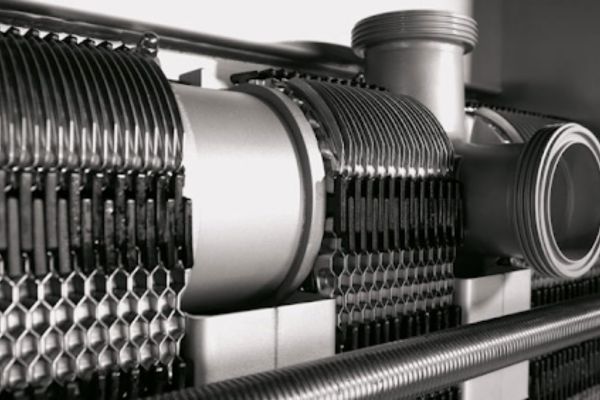

It is a device that transfers heat from one medium to another. This process helps control temperatures, improve efficiency, and prevent equipment from overheating. In industrial setups, these devices are used to control temperature in various processes, such as cooling down machinery, heating substances, or maintaining an ideal temperature for production.

Factors to Consider When Choosing the Right Heat Exchanger

Here are the factors you must consider when purchasing manufacturing heat exchangers:

1. Temperature Requirements

Different processes require varying temperature ranges for optimal performance. You need to choose a device that can handle the temperatures your system demands. For example, if your manufacturing plant deals with high-heat processes like chemical production or metalwork, you need a heat exchanger that can handle extreme temperatures.

2. Size and Capacity

The size and capacity of the heat exchanger should match your needs. If the heat exchanger is too small, it will not be able to handle the volume of heat required, which can lead to inefficiencies and system failures. On the other hand, if you choose one that’s too large, you might have to spend a lot of money on its purchase and maintenance.

3. Flow Type

There are two main types of flow in heat exchangers: counterflow and parallel flow. In counterflow heat exchangers, the two fluids flow in opposite directions. This setup is more efficient for heat transfer, making it perfect for high-performance applications. On the other hand, parallel flow heat exchangers have fluids moving in the same direction, which is less efficient but may be ideal for simpler applications. When selecting a heat exchanger, it’s important to consider the flow needs of your manufacturing process.

4. Material Compatibility

The materials used in a heat exchanger must be suitable for the fluids or gases it handles. For example, heavy equipment manufacturers working with large machinery use chemicals or high temperatures. They need heat exchangers made from materials that won’t react with these substances. Stainless steel, titanium, and certain alloys are used for their strength and durability. It’s important to make sure the heat exchanger’s material matches the fluids being heated or cooled.

5. Maintenance

Heat exchangers require regular maintenance to ensure they perform optimally. Some heat exchangers are easier to clean and maintain than others. When choosing a manufacturing heat exchanger, it’s critical to consider the maintenance requirements and how much time and effort your team can give to keep it running smoothly.

6. Budget

High-quality heat exchangers come with a big price tag, but they provide long-term savings through energy efficiency and reduced downtime. However, it’s important to work within your budget while also considering the long-term benefits that a more expensive, efficient heat exchanger, like a gas-gas exchanger from companies like Godrej Enterprises Group, may bring.

Also Read: What is ULIP? Understanding ULIPs with an Easy ULIP Calculator

Conclusion

Choosing manufacturing heat exchangers for your company is not a simple task. But by keeping in mind the temperature needs, size, materials, and types of flow, you can make a well-informed choice. Efficiency, maintenance, and budget are also major considerations that will help you with your decision. If you keep these factors in mind, you can easily find a heat exchanger that can fulfil your business needs.

Elets The Banking and Finance Post Magazine has carved out a niche for itself in the crowded market with exclusive & unique content. Get in-depth insights on trend-setting innovations & transformation in the BFSI sector. Best offers for Print + Digital issues! Subscribe here➔ www.eletsonline.com/subscription/